Grain Handling

We’re committed to building customized grain-handling sites. That commitment includes installing quality bucket elevators, conveying systems, and pneumatic blowers.

Bucket Elevators

Our energy-efficient bucket elevators gently handle free-flowing bulk materials such as grain, fertilizer, livestock feed, poultry feed ingredients, and aggregates. Premium components include galvanized buckets, rubber belts, and engineered bearings and shafts. Material discharged at up to 150 feet in height and 10,400 bushels/hour. Housed in a durable steel body.

Conveyors

Maximize throughput, reduce downtime, and increase overall productivity. Versatile and ruggedly built, our conveyors move grain smoothly, efficiently, and continuously. Customize your conveyor with speed adjustments and various configuration options. Adaptable to a wide range of loading, unloading and grain transfer applications.

Incline Drag Chain Conveyors

Norstar incline drag chain conveyors ensure efficient material handling, saving time and money. Conveying on steep inclines can lead to reduced capacity. Less throughput equals inefficiency and wasted resources, these are designed to transport bulk materials at steep inclines.

Features

- Self-Cleaning: Curved back plate in tail section prevents material buildup.

- Quiet Operation: UHMW paddles and return rollers minimize noise and wear.

- Product Protection: Elongated discharge prevents crush/pinch points, ensuring product quality.

Options

- Capacity Range: 1,000 – 40,000 Bushels Per Hour (BPH)

- Conveyor Size: 9″ to 44″ wide

- Incline Range: 15° to 45°

- Finishes: Powder Coated, Galvanized, Stainless Steel

Screw Conveyors

Norstar Screw conveyors facilitates smooth operation of any system, facilitating the movement of products from one point to another with ease. This is a tailormade solution to handle a wide range of free-flowing materials efficiently

Features

- 6″ – 24″ Models

- Standard Formed-Flanged U-Trough Design (Tube Conveyors also available)

- Fully Enclosed Body, Standard Helicoid Flighting (other options available)

- Enhanced Auger Flighting: Thicker edge for higher capacity and longer lifespan.

- Smooth Rotation: Split-Wood Hanger Bearings minimize wear and noise. Other bearing options available.

Options

- Capacity Range: Varied based on conveyor size, speed, and handled commodity. Conveyor Sizes: 6″ to 24″ wide.

- Finishes: Powder Coated, Galvanized, Stainless Steel.

Pneumatic Blowers

Ensure efficient, long-lasting grain handling and transfer. Our pneumatic blowers are engineered for powerful, consistent airflow. Operation is pleasingly quiet, thanks to advanced noise-reduction technology. Solidly built with quality materials for dependable long-term service.

Unload Augers

Maximize your efficiency with our range of unload augers, designed for fast and reliable grain transfer. Featuring innovative technologies such as wear edge protection and unique U-trough designs, our unload augers ensure minimal grain damage and reduced downtime during unloading operations.

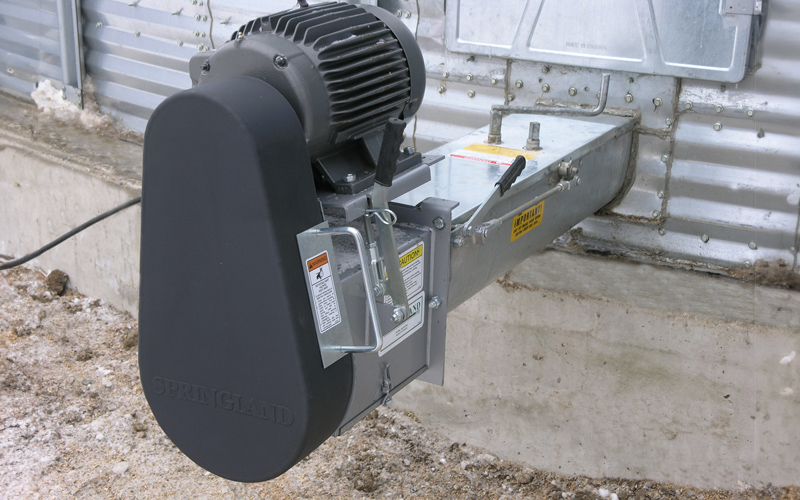

Springland U-trough Unload System

The Springland U-Trough design moves more material than traditional round tubes at the same horsepower with less chance of grain damage.

Features

- Ease of installation, top-quality materials, and proven design

- Unloaders fit typical bins ranging from 18 to 78 feet in diameter.

- Available with 7.25”, 8.25” and 9” sweeps

- Unloading at 5,000 to 7,500 Bushels (136-200Mt) per hour. Capacities may vary depending on grain type and condition.

Electric Powerhead

Electric Powerhead – Motor mount with over-center belt tensioner. The belt guard swings out for easy access to belts. Motor, pulleys, and belts are not included.

Hydraulic Powerhead

When electric power is not available. Suitable for bins up to and including 48 ft diameter.

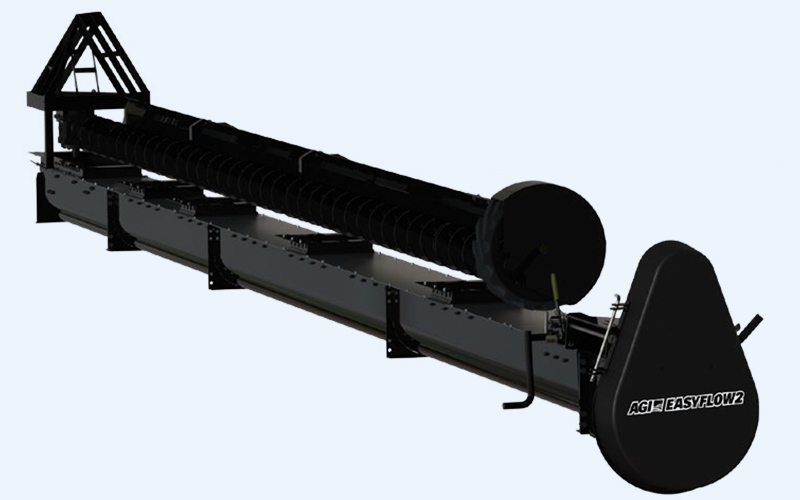

Westeel Bin Unloads

AGI’s unload systems are designed for the rigours of on-farm use and feature superior durability, strength and performance. Make grain clean-out easy and efficient with the AGI Tube or U-Trough unload systems.

Features

Available for bin sizes from 21’– 60’ in diameter

11” Standard Output U-Trough capacities from 5,000 to 7,500 BPH, complete with center and intermediate sumps and gates

11” High Output U-Trough capacities of 6,800 from 9,000 BPH, complete with center and emergency sumps

U-Trough extension kits available (3’, 4.5’, 5’, 6’ & 9’)

Available in electric and hydraulic powerheads

Standard Output U-Trough Unload

Available for bin sizes from 21′ to 60′ in diameter

5,000 – 7,500 BPH

High Output U-Trough Unload

Available for bin sizes from 24′ to 60′ in diameter

6,800 – 9,000 BPH

Tube Unload

Available for bin sizes from 24′ to 48′ in diameter

8″ – 3,000 BPH